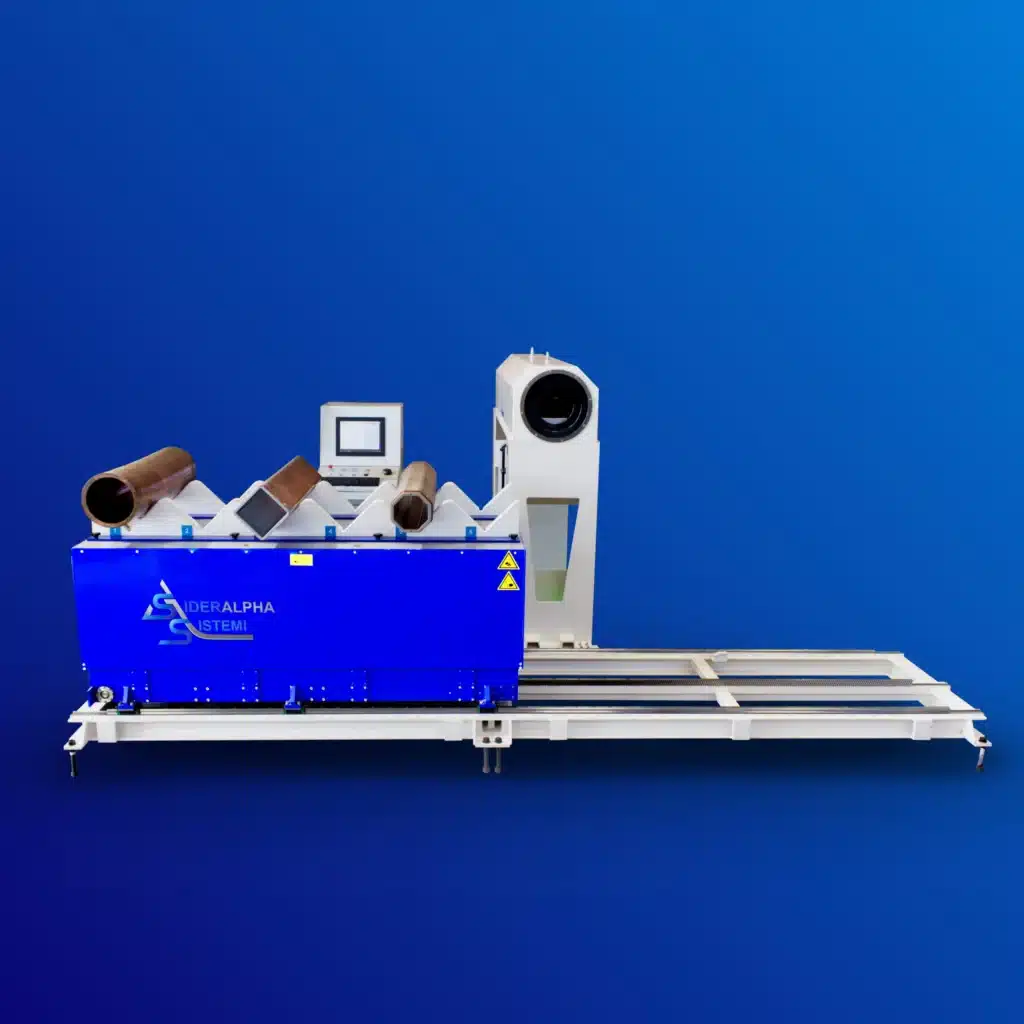

MCS is a fixed installed and fully automatic station for mould internal geometry scansion (using laser technology). It can be used in CCM Workshop for mould inspection (used mould check or new mould acceptance) or by copper mould producers for product quality check and certification.

MCS supports up to 6 mould loading for automatic sequential scanning. It performs a complete mould checking due to the 360 degrees scanning. It can checks mould’s shape, squareness, ovalization, bending radius, corner radius, and more.

MCS station is available in two versions: horizontal mould loading (MCS-H) or vertical mould loading (MCS-V). Both versions support interchangeable measure heads for a wide range of measures.

Measure results and acquired data can be integrated with third party systems using a dedicated software API for communication.

Contact us if you have

need more information

Download the Product

Presentation Brochure

Request the detailed technical

specifications of the EMTM33 tool

| FEATURES | VALUES |

| Taper form supported | Round, Square, Rectangural and Octogonal Diagonal range from 130mm to 500mm (using different measure heads) |

| Technology | Triangulation laser sensor |

| Resolution | +/- 0.005 mm |

| Accuracy | +/- 0.02 mm |

| Repeatability | +/- 0.03 mm |

| Longitudinal measurement step | from 5 to 50 mm |

| Measurement time (1000mm taper lenght) | 10′ (25mm step) / 50′ (5mm step) |

| Operator Interface | Stand-alone totem with touch display PC |

| Mould loading capacity | up to 6 |

Mould taper check benefits:Economical gain due to:

|

|

MCS-V is a variant of MCS mould checker station. Moulds are loaded into a rotating carousel. The carousel can be designed to accomodate up to 6 moulds.

Thanks to the interchangeable laser head, MCS can be provided with a set of different range measure head. Using a complete set, the range of measurement diameters can span from 130mm to 500mm.

available from 8:00 – 18:00 (GMT+1)

Address A. Pacinotti, 26 – 57025 PIOMBINO (Italy)

Email info@sideralpha.com