The Productivity evolution in Continuous Casting Plant (casting speed ) is directly connected to the Mould’s shape and the primary steel solidification process. The dimensional and geometrical control of the mould assume a basic importance. The frequency of the surveys and the know ledge of the Mould status is warranty for the Product Quality. From such consideration it is born the need to have tools able to get such information in fast and easy way.

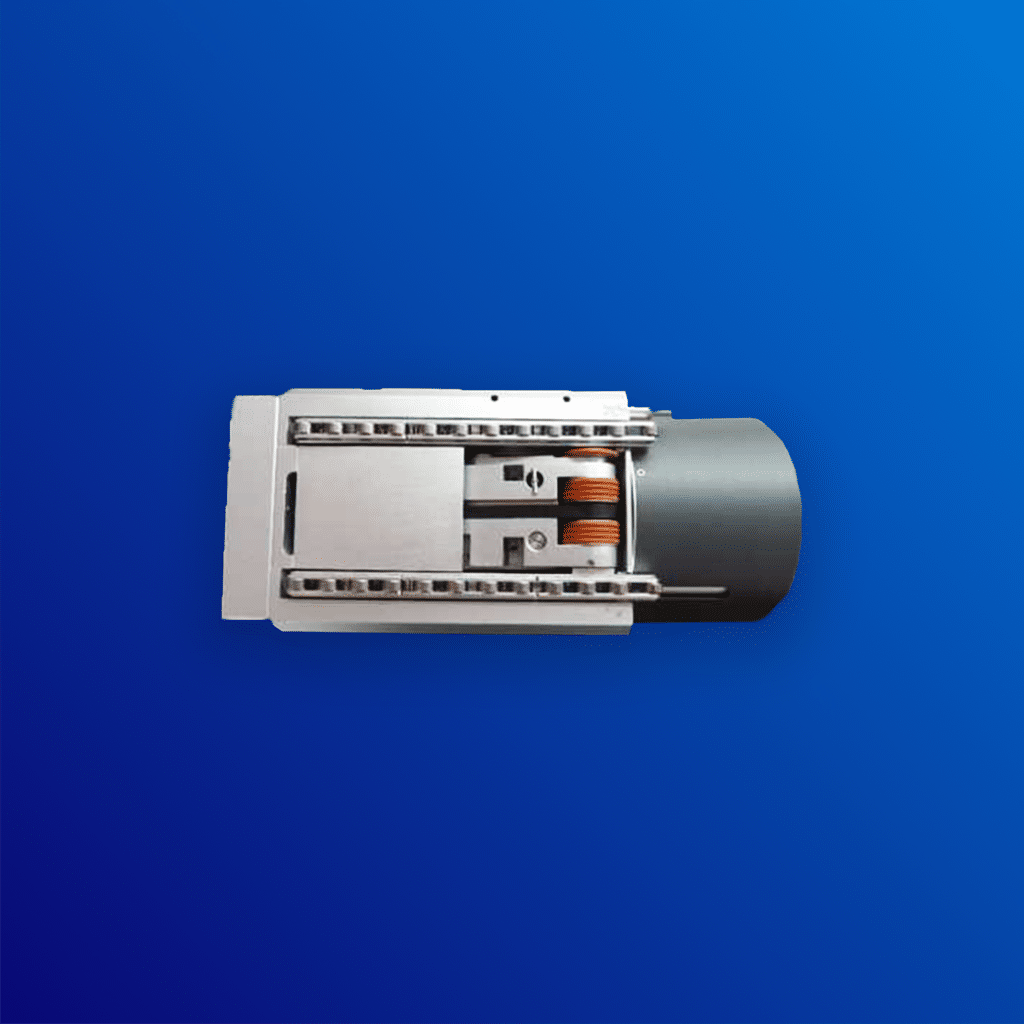

The Emtm67 is an instrument designed to satisfy the operators needs to perform the Mould measurement in way easily, fast, accurate and everywhere. The most important feature, beyond the accuracy and a rich Sw, is the lightness and his manageability. The whole system is contained in a transportable trolley (<30Kg).

By the Laser sensor a 360° scanning is possible at different settable steps. The data elaboration allows to get Longitudinal Graphics , Slices and 3D representation.

It can be used indifferently in Workshop or on Casting floor by one operator without crane or lifting means. It can operate in Horizontal or Vertical position. After the preliminary setting operation the instrument performs the measurements in automatic way without the operator assistance.

Contact us if you have

need more information

Download the Product

Presentation Brochure

Request the detailed technical

specifications of the EMTM33 tool

| FEATURES | VALUES |

| Taper form supported |

Round (diameter form 130 to 220 mm) Square (diagonal from 140 to 200 mm) Octagonal (diagonal from 140 to 200 mm) Different sizes on request |

| Technology | Triangulation laser sensor |

| Resolution | +/- 0.005 mm |

| Accuracy | +/- 0.02 mm |

| Repeatability | +/- 0.03 mm |

| Longitudinal measurement step | from 5 to 50 mm |

| Measurement time (1000mm taper lenght) | 10′ (25mm step) / 50′ (5mm step) |

| Data transmission | WiFi |

| Battery operative time | 8 hours |

| Environmental Protection | IP62 |

• Scanning of the whole internal mould’s surface

• Light, versatile and easy to use in CCM and Work-shop.

• Wide measurement range

• Able for Billet, Bloom and Round

• Taper, Diagonal

• Data storage

• Display on Display and P.C touch screen. Graphics, Tables, 3D

• Wire less data transmission.

• Data transferring to HMI

• Laser measurement technology [360°]

Mould taper check benefits:Economical gain due to:

|

|

available from 8:00 – 18:00 (GMT+1)

Address A. Pacinotti, 26 – 57025 PIOMBINO (Italy)

Email info@sideralpha.com