RDLS is an innovative modular system for CCM strand monitoring. Its lightweight modules are installed on dummy bar for data acquisition during DB movement operations. The modular system’s versatility allows that up to 6 modules can be placed in the DB Head during the normal introduction without waste of production time, allowing the CCM control when desired.

RDLS modules can acquire roll’s gap, alignment and rotation status. Using an additional module it can also check the water spray efficiency. The system can be composed by:

– From 2 to 6 modules for rolls data measurement (gap, alignment and rotation)

– An optional water spray check bar

The system’s modules can be installed on a dedicated shell for permanent installation on dummy bar (In-Chain version).

Contact us if you have

need more information

Download the Product

Presentation Brochure

Request the detailed technical

specifications of the EMTM33 tool

| FEATURES | VALUES |

| Supported CCM Types | Top Feeding / Bottom Feeding Slab thick from 50 to 300 mm |

| Roll Gap | +/- 0.1 mm (accuracy) +/- 0.02 mm (resolution) |

| Roll Alignment | +/- 0.05° (accuracy) +/- 0.005° (resolution) |

| Roll Rotation | Qualitative indication: from 0% (blocked roll) to 100% (free roll) |

| Water Spray efficiency (OPTIONAL) | Qualitative indication: from 0% (occluded) to 100% (fully functional) |

| Weight | <20Kg (single module) |

| Data transmission | WiFi |

| Battery operative time | 6 hours |

| Environmental Protection | IP67 |

| Mould taper check benefits: | Economical gain due to: |

|

|

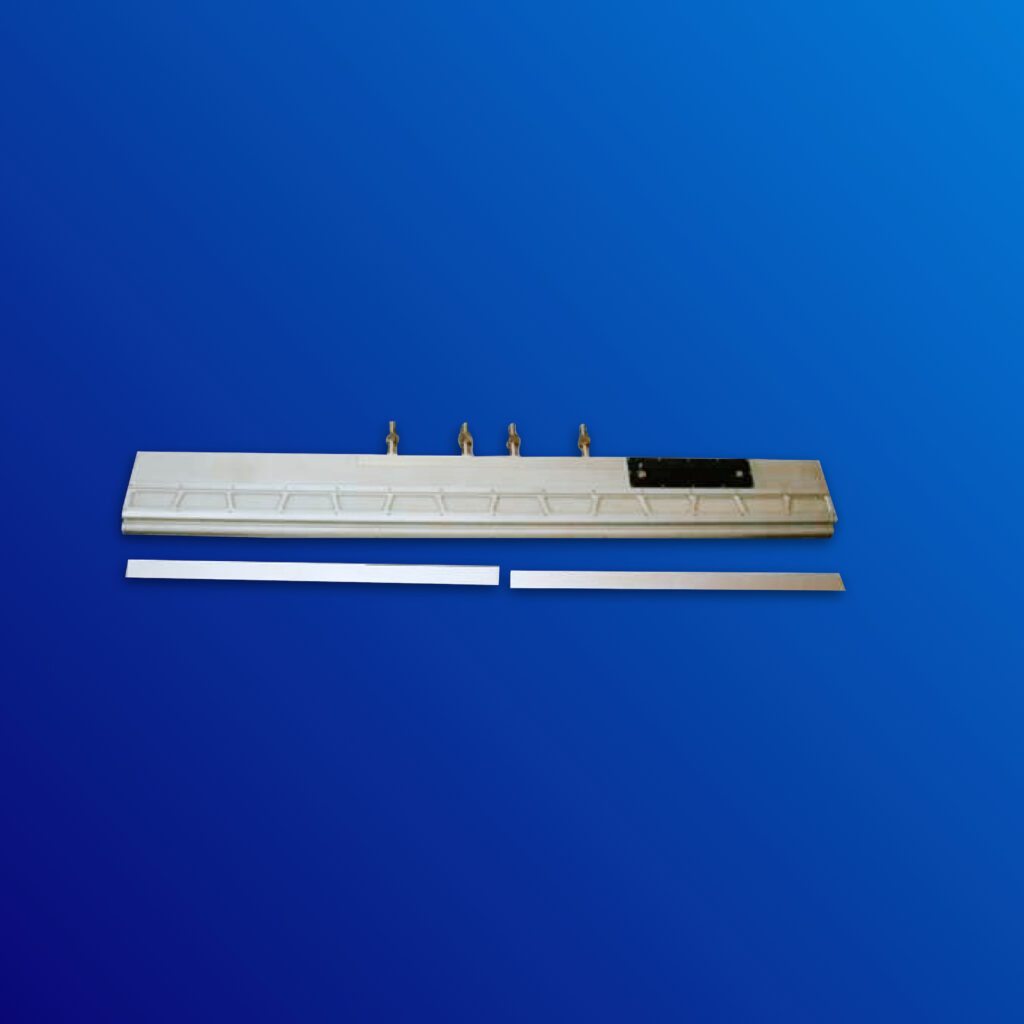

Addictional module for secondary cooling system monitoring. It can measures the efficiency of segment’s water spray.

RDL modules shell for permanent installation on dummy bar. Designed to keep on line under control the plant geometry.

available from 8:00 – 18:00 (GMT+1)

Address A. Pacinotti, 26 – 57025 PIOMBINO (Italy)

Email info@sideralpha.com